Sustainability leaders

Technology Innovators

Industry Experts

Globally Trusted

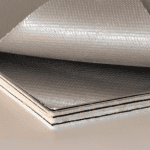

Lamination Press Pads

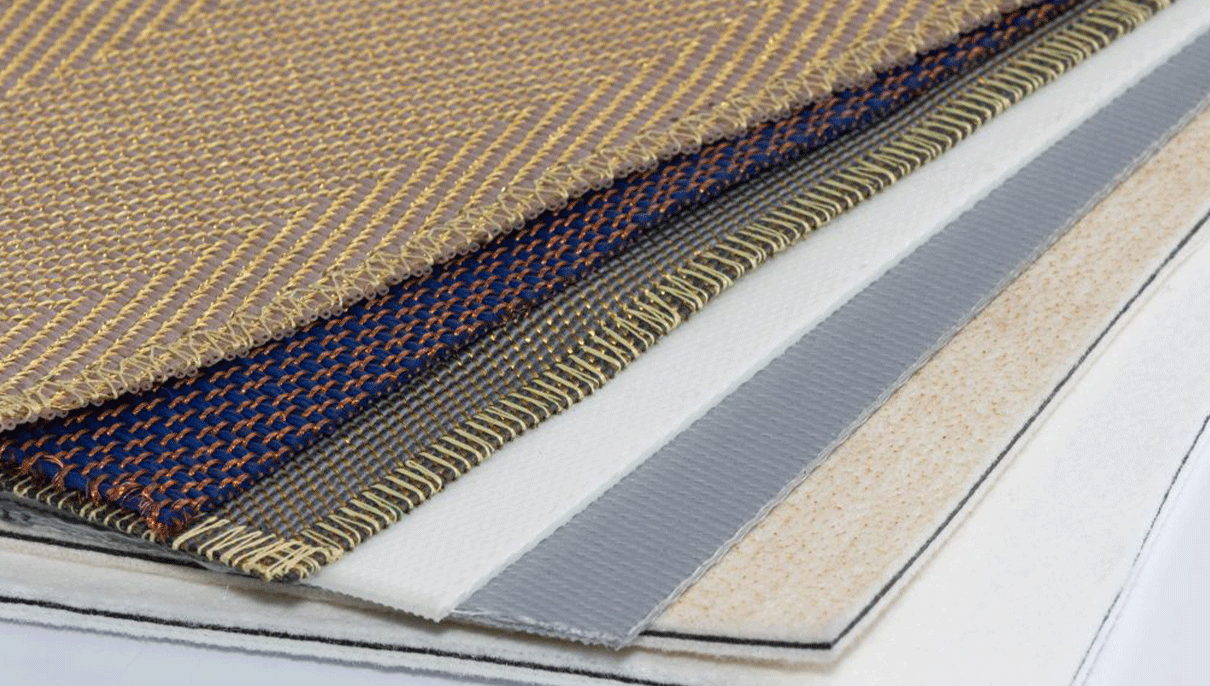

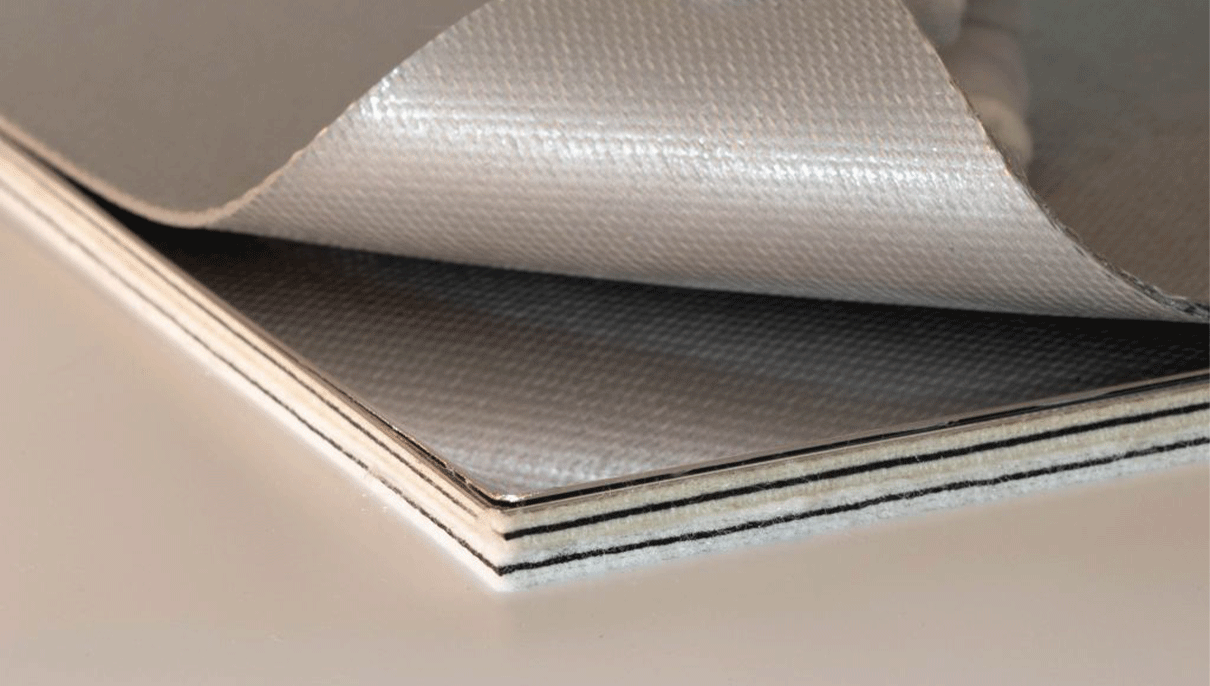

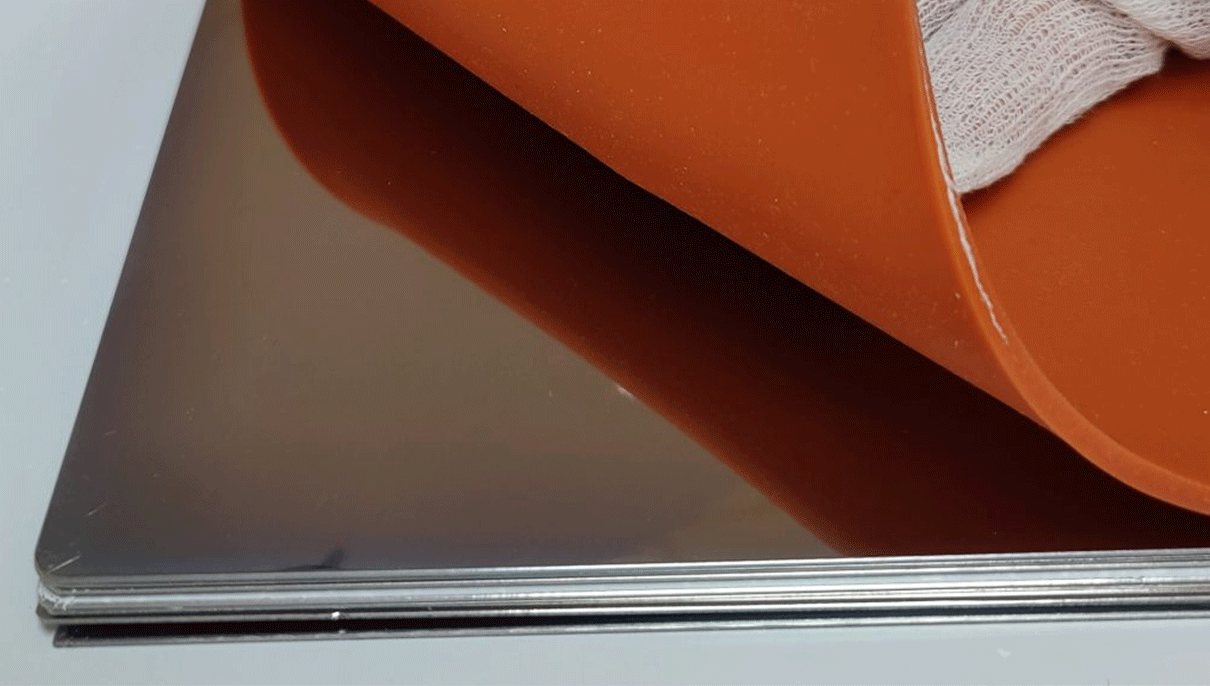

Our lamination press pads are designed to ensure consistent heat and pressure distribution, delivering high-quality results for identity card and passport production. These precise pads are essential for creating secure and long-lasting ID cards and passport data pages.

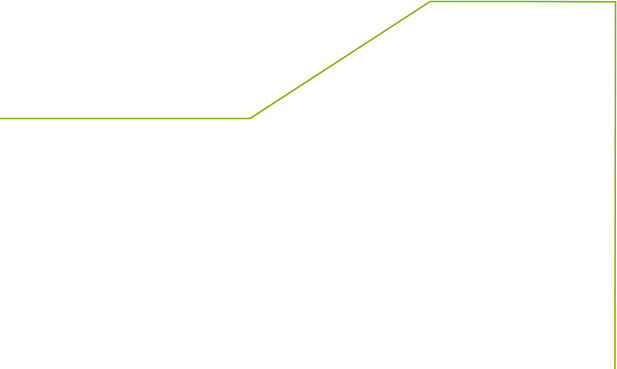

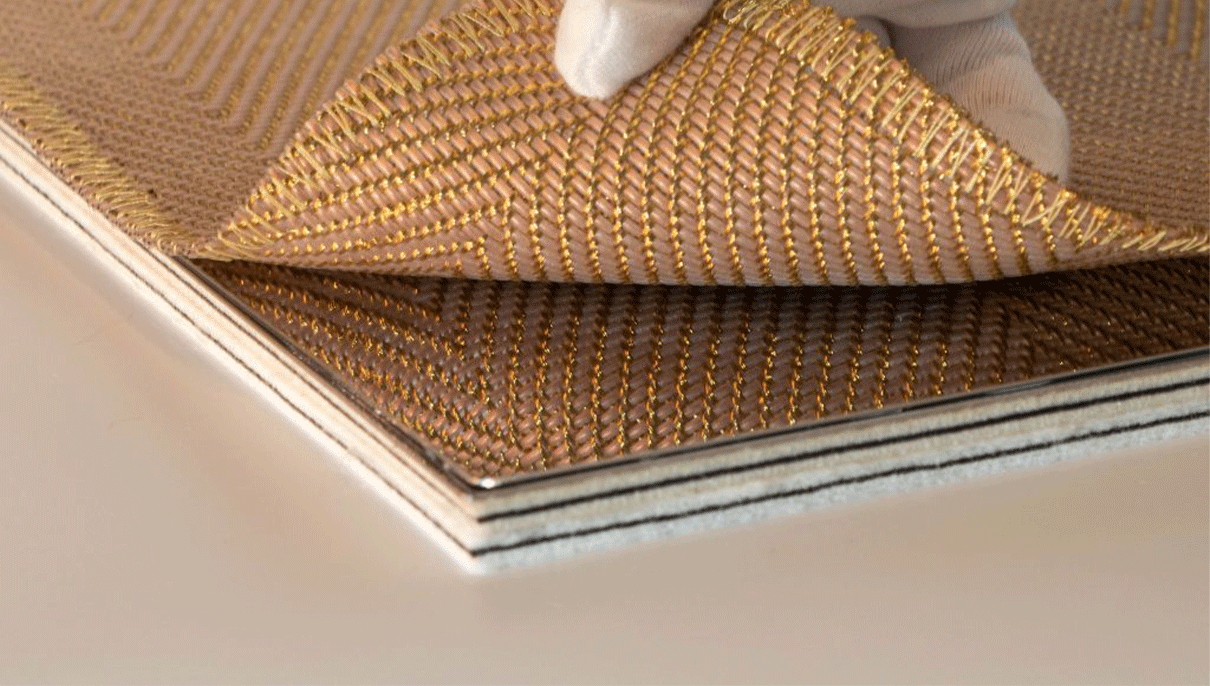

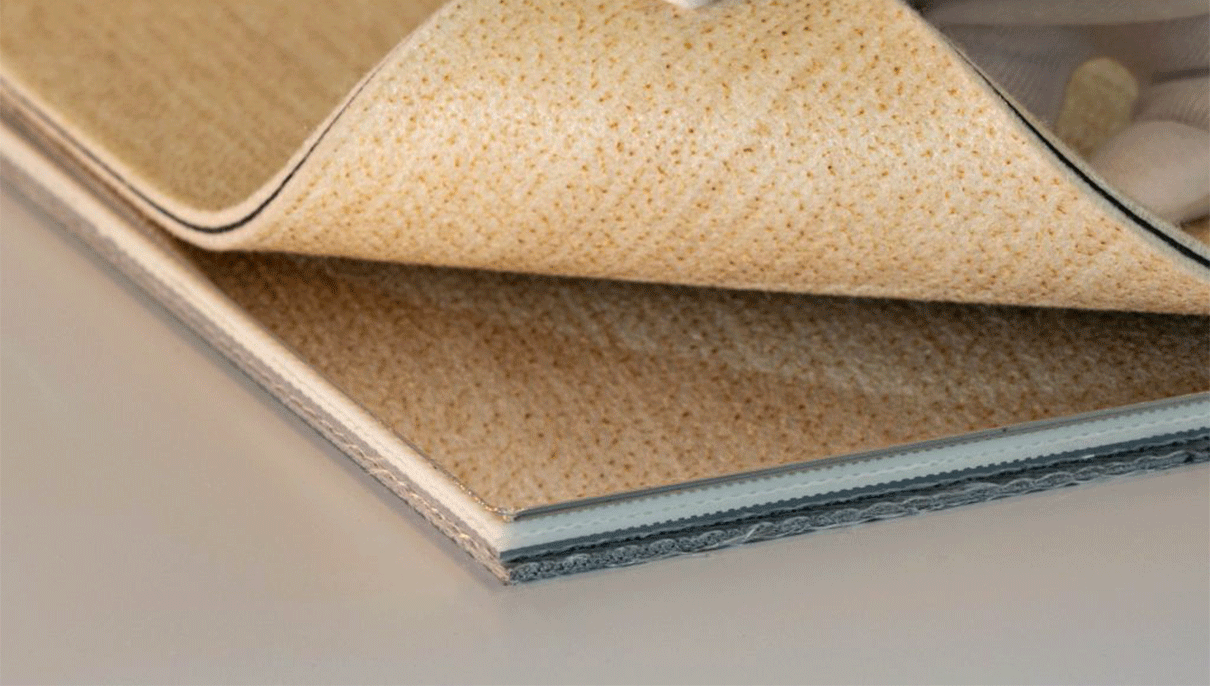

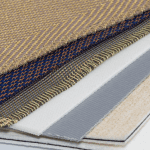

Our technicians work closely with you to ensure we understand your operating environment and any specific requirements so we can offer the most appropriate pad construction. Cardel pads are available in a range of materials and composite layered formats, using aramid, butyl rubber, silicone, brass, and copper.

Cardel also provides high-quality lamination plates and cassettes, polycarbonate, and more for the production of identity cards and passport data pages.

Request quote

Request free brochure

Request free brochure

Why Choose This Service?

Pressure Balance

Our lamination pads deliver smooth and consistent pressure compensation to ensure consistency in the end product without increasing cycle times.Waste Reduction

Cardel pads are designed to reduce waste during the lamination process, significantly increasing yield.Financial Benefit

Our unique pad range allows our customers to make tangible savings from production efficiency and waste reduction, while ensuring a high-quality end product.

Description

- Cardlam 200™ – a composite lamination pad that is designed to ensure hiqh quality lamination of all types of Credit, Bank and Loyalty cards. The performance of the pad ensures:

- Smooth control over heat and pressure distribution (Hot and Cold stages)

- Excellent pressure compensation qualities.

- Good durability – typically 2000 – 4000 operations.

- Compatible with all types of high volume laminators.

- Easy handling – suitable for tilt table systems.

Suitable for all types of medium / high volume twin stack laminators and is also used extensively in single stack laminators producing lower volumes. Proven to assist in the elimination of lakeing, frosting and significantly reduce edge distortion that can occur in card lamination.

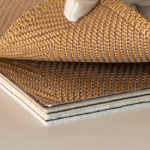

- Cardlam 220™ – developed for specific use in high performance lamination of Credit and Smart cards achieving:

- Increased lamination output volume versus other pad types via reduced cycle time

- Rapid heat transfer to achieve core to core bond in the centre of the stack.

- Excellent compression recovery qualities.

- High durability – typically 4000–6000 operations.

- Compatible with all types of Single and Twin Stack lamination machines.

- Easy handling – suitable for tilt table systems

10% to 15% increase in lamination output is achievable with Cardlam 220 pads due to the rapid and even heat distribution. The pads are also easy to handle, do not stick to the lamination platens and are suitable for tilt table systems. The C220 pad can also be supplied as C220+ which is 50% thicker due to increased layer of Silicone in the centre of the Pad. The additional thickness increases the compensation properties of the pad with minimal effect on the Heat transfer speed.

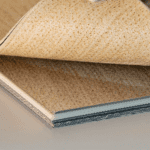

- Cardel Cardlam 220 WS – developed for specific use in high performance lamination of Credit and Smart cards achieving:

- Rapid air evacuation from the stack during compression via bespoke surface profile texture.

- Increased lamination output volume versus other pad types via reduced cycle time

- Rapid heat transfer to achieve core to core bond in the centre of the stack.

- Excellent compression recovery qualities.

- High durability – typically 4000–6000 operations.

- Compatible with all types of Single and Twin Stack lamination machines.

10% to 15% increase in lamination output is achievable with Cardlam 220 WS pads due to the rapid heat distribution. The pads are easy to handle, do not stick to the lamination platens and are suitable for tilt table systems.

- Cardel Cardlam 220 RS – offers the following properties:

- Smooth surface to prevent transference of pad surface profile / texture.

- Increased lamination output volume versus other pad types via reduced cycle time.

- Rapid heat transfer to achieve core to core bond in the centre of the stack.

- Excellent compression recovery qualities.

- High durability – typically 4000–6000 operations.

- Compatible with all types of Single and Twin Stack lamination machines.

10% to 15% increase in lamination output is achievable with Cardlam 220 WS pads due to the rapid heat distribution.

Choose Cardel

Cardel Group subsidiary VTT is one of the most trusted brands in the field of secure and efficient manufacturing of documents with more than 25 years of experience and expertise.

With a broad portfolio of innovative secure technologies and efficient solutions all products are customized to optimize your processes while taking security to the next level.